Our

Company

INLIGHT GmbH & Co. KG is a medium-sized company which was founded in 2007. INLIGHT is specializes in the development and OEM manufacturing of emergency- and safety luminaires, as well as the corresponding systems. The product distribution and sales in Germany and abroad takes place exclusively via authorised sales partners.

Our customers' requests are our highest priority which we prove by means of our extensive service. Not only does the product quality make us a suitable partner,

but also our flexibility, speed and service.

The INLIGHT team currently comprises more than 90 highly motivated employees in the various divisions.

Our Workspace

Since January 2013 the company has been in the new offices in the industrial park Hünxe, where, on a 7,000 m² property, an effective area of 2,000 m² was used in the first step. In January 2015, the second construction phase was completed, giving the company approximately 3,500 m² of floor space in the various areas. As a result of further expansion of the building in 2019, the company now has around 4,500 m² of usable space available. In addition, adjoining buildings and land were acquired, bringing the total now available space to approximately 6,000 m² and the land area to approximately 12,500 m².

The warehouse and logistics area covers an area of approx. 2,700 m² and accommodates large handling areas as well as a small parts warehouse and a high-bay warehouse with a capacity of approx. 2,500 euro-pallets. Raw materials and semi-finished products for several months are stored, which not only offers maximum availability when orders fluctuate, but also ensures that delivery dates can be aligned to customer requirements.

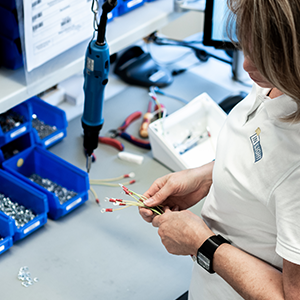

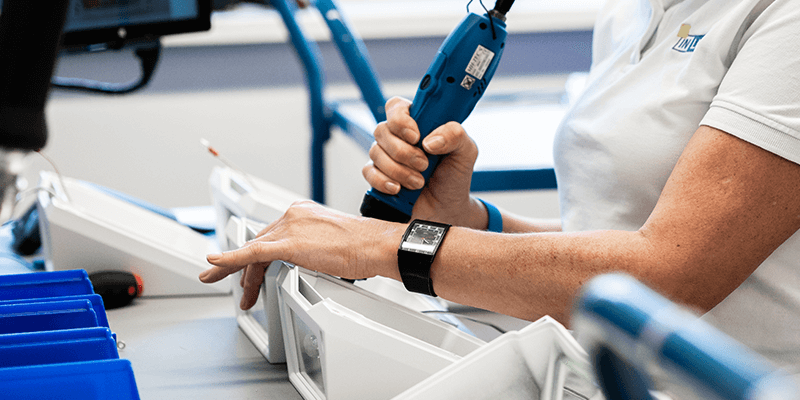

In the area of production, final inspection and packaging, the company has up to 90 workstations with an annual capacity of up to 350,000 units on an area of approx. 800 m². From the delivery of the raw material to the delivery of the finished product, optimally coordinated processes and the specific know-how of our qualified employees ensure the best production conditions and excellent results.

Become part of our team

Our employees are significantly involved in the success of our medium-sized company for emergency- and safety luminaires.

We want to grow our business and are looking for further support.

The services we can offer you

We are your partner for the design, development and production of innovative, individually customised, safety lighting systems. In this respect, we combine the flexibility and straightforwardness of a young, dynamic company with the greatest competence and decades of experience.

Production

Being primarily an OEM, we manufacture safety lights with individually customised branding and the best price/performance ratio.

By using state-of-the-art IT systems, we are able to achieve processes that are optimally tuned to our customers‘ requirements. In the process, we are able to guarantee short delivery periods, top quality products and process stability. Let us demonstrate our services to you personally – get in touch with us.

Developement

Within the framework of product development, we uniquely combine individually, customised designs realised using newly created tools with our extensive range of standardised, safety lighting modules. This combination enables us to translate ideas into products ready for production in a really short amount of time and furthermore to ensure that all products are equipped with tried and tested technology. By virtue of the fact that our developers are constantly working in national and international compliance committees, we can also ensure that emerging trends are included in product development at an early stage.

Design

Our designers design safety lights based on individual requirements. If requested, we can produce prototypes to scale so that final decisions can be made as to whether the designed product not only fulfils requirements on paper, but also in practice. In this phase, attention is paid to there being close interaction between designers, developers and production to ensure that nothing stands in the way of subsequent implementation.

Our promise to deliver quality

Quality is the basis of the long-term relationship we aim to achieve with customers in the spirit of partnership.

Quality is not just a word to us; it is an omnipresent part of our day-to-day work.

Employees

Experienced and well trained employees are the basis of our business success.

Products

Our products fulfil the highest quality requirements.

Processes

We are always developing all internal and external processes.

Durability

All of our products are subjected to constant, extensive endurance tests .

Our associations

We would like to be able to recognise developments on the market early on, act upon them and, above all, actively help shape them. That is why we are members of ZVEI, and actively collaborate with mainly German and international associations and agencies involved in emergency lighting.